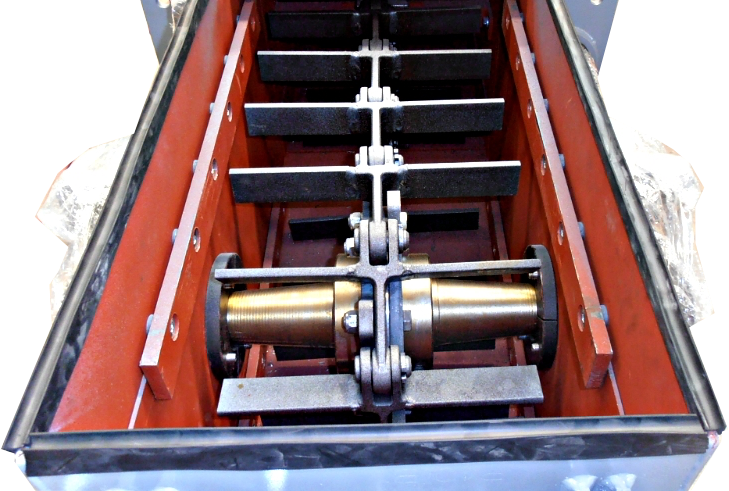

Chain conveyors are usually closed type conveyors. The material is loaded into the conveyor at any point and conveyed along the groove by the scraper fins. Emptying of transported material can be done from any or more points along the conveyor. Manual or pneumatic covers are used if discharging is done from more than one point. Chain conveyors can carry materials at the same time in the lower and upper parts and, when necessary, it can transport materials in opposite directions. For chain conveyors, single or double chains are used as pulling component.

Chain conveyors are used to transport various powders, grains and free – flowing materials. It is not suitable for transporting fragile, moist and sticky materials.

The reasons for preferring the chain conveyors can be summarized as below:

• The simplicity of the design and the durability of the structure,

• Ability to carry material in two places in upper and lower sections,

• Easy loading and unloading from desired points along the conveyor.