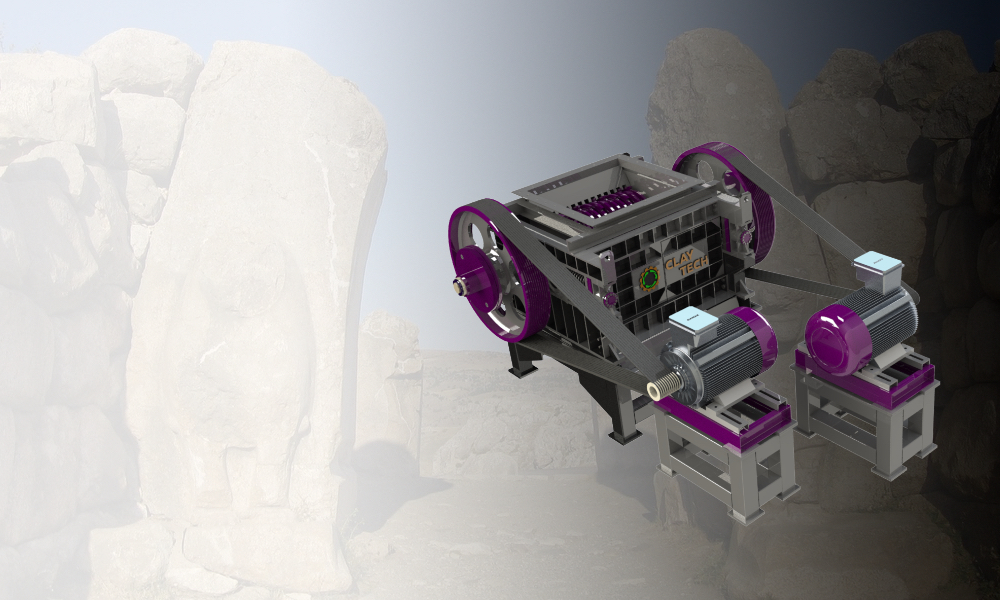

Initially cement industry and so many mining industries can use this type machine. This machine can be considered as the primary crusher. It ensures that the first material coming from the mine, breaks 0-600 mm to 0-60 mm. Crusher is applicable for adhesive feed material The machine completely is produced with steel construction.

The machine safety system has two different forms. The first one is designed with safety pin on the pulley by calculating mechanical energy and torque from the machine. The safety pin breaks when foreign material runs between the two rotors or when it is forced to break more raw material than medium hardness. The second is that due to the spring mechanism on which the bearings are based, the rotors act when the safety pins do not function. At this point the machine body or parts are still working without being damaged.

Machine rotors produced from steel casting. The rotors, which are quite compact, are welded with special hard facing flux cored wires

Scraper blades have been selected from special materials and welded with special hard facing flux cored wires to prevent sticking of raw material to the rotor due to moisture.

The side and top parts of the rotors were made resistant to wear with 400 brinell sheets The machine has self-lubricating automatic (self-controlled) lubrication technology.

Different types and sizes of machines can be manufactured according to the capacity.

Rotorlar arasında hammaddenin nemden dolayı yapışmasını engellemek için sıyırıcı bıçaklar özel malzemeden seçilmiş olup, özel sert dolgu özlü tellerle kaynatılmıştır. Rotorların yan ve üst aksamları 400 brinell sac ile aşınmaya mukavim hale getirilmiştir. Makine kendi kendini yağlayabilen otomatik (kendinden kontrollü) yağlama teknolojisine sahiptir.

Kapasiteye göre farklı tip ve ebatlarda makine imalatı yapılabilmektedir.