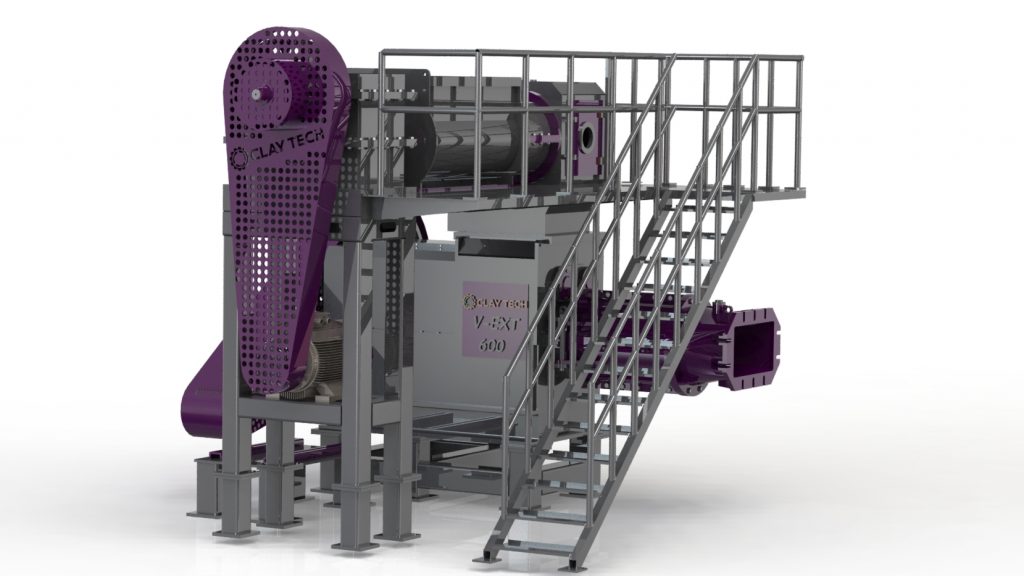

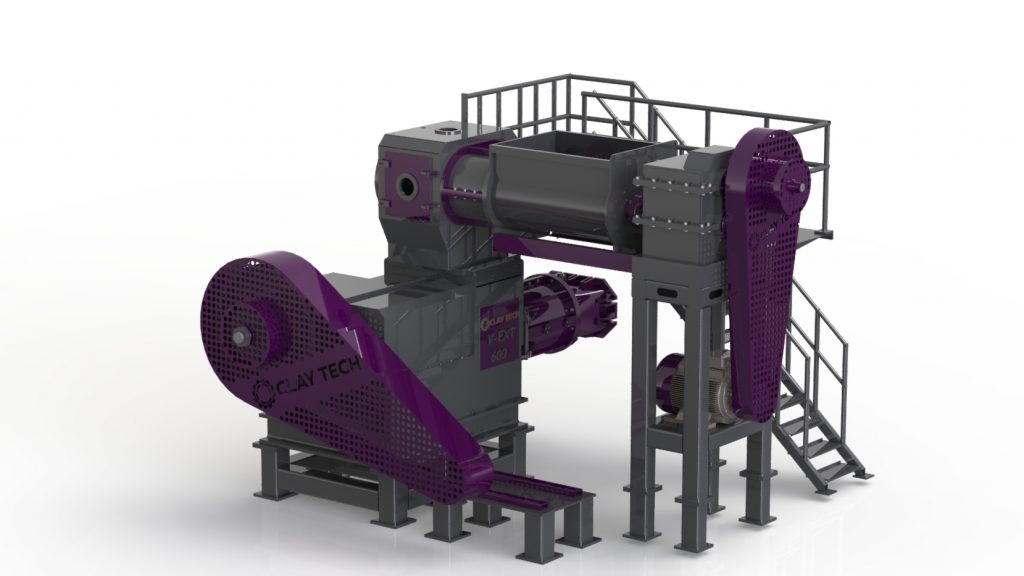

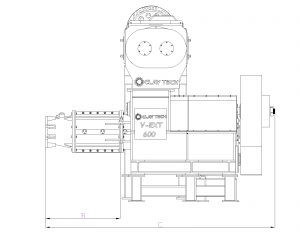

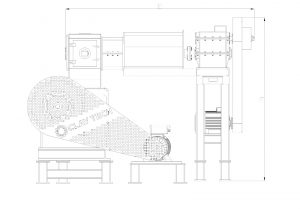

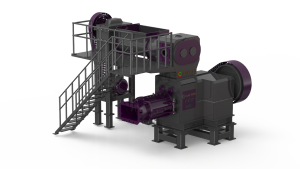

Vacuum extruder brick making machinery is used to coat the different shape base material with brick and similar clay raw material. The mould box connected to the tip of the machine presents the two dimensional shape of the product. The third dimension is available by means of cutting operation. The up and base machines are designed with helical gear. They drive the two reducer on vacuum extruder brick making machinery. Reducer system works a clutch system while the clutch system is working with air (pneumatic).

It is important to keep in mind that that the machine is produced completely with steel construction. Apart from this, the montage is applicable by using different methods, such as keeping the upper part of the machine parallel to the lower part or turning it 90° with it. It is possible to obtain the product through the vacuum extruder machine in wet ratios 17-20%.

Without a doubt, the clay brick and tile Smart Vacuum Extruders (monitoring system) are designed to achieve the best performance, minimized maintenance tasks and reduced operation cost, whilst operating in the most demanding of conditions. The Clay Tech extruder and pugmill range gathers every CLAY TECH experience of extruding clay products. As the leading edge of Vacuum Extruders (brick making machinery), it is usable commonly for briquetting different kinds of mineral wastes.

Moreover, a wide range of sizes and configurations – with augers from Ø 450 to Ø 750 mm – allow the Clay Tech to provide excellent flexibility and adaptation to differing extrusion conditions.

– Investment adapted to needs

– Optimisation of operating costs

– Accessibility for maintenance

– Efficiency in mixing and extrusion

– Safety and control

– Maximum versatility

Monitoring system on vacuum extruder brick making machinery

Temperature control : Bearings has the probes to measure the temperature. Probes with connects to indicator or PLC. If there is any problem for the bearings PLC will give warning.

Vibration control :Bearings has the probes for the measure the vibration. Probes with connects to indicator or PLC. In the same way, if there is any problem for the bearings PLC will give warning.

System of automatic lubrication and cooling : First, system sucks the oil in the machine, filters and cools it. Then it pumps the oil in machine and finally lubricates the bearing and gears.

System of automatic grease lubrication: As a mark based in Germany, the Grease pump give the grease to unlubricate fluid oil. It is important to emphasize that the pump lubricates 10 different points.

Machine health monitoring system with PLC : Since the equipment has the touch screen, it is possible to control clearly the vibration and temperature of the lubricate with PLC.